-40%

Scale Marked Screed Leveling Tripod/ 20ea-"no corrod " "140g"

$ 180.93

- Description

- Size Guide

Description

Scale marked screed leveling tripod•

It is for checking the height of the liquid mortar.

•

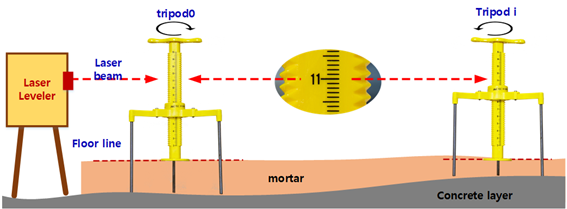

How to align the laser line to the central axis ruler for ease of use.

•

Unique corrosion resistant all stainless steel and ABS.

•

Folds for convenient storage and transport box storage.

•

Adjustable height between 5 and 110mm material depth.

•

Scale display support range 20 ~ 160mm

•

Easy and fast installation with multiple laser levels and multiple personnel

•

Stability of position with a product weight of 140 grams

< Picture and Description >

※

Caution

(1) Reproduction of this manual in whole or in part is prohibited.

(2) The contents of this manual are subject to change without notice.

(3) If you have any questions, such as where the contents of this manual are incorrect or where the description is missing, please contact J & C Tech.

Handling precautions and recommendations

☞

This screed leveling tripod is a reusable product.

☞

When storing, it is recommended to lubricate and store foreign substances on the ruler part with water.

☞

Be careful of damage caused by falling, hitting, cleaning, etc.

☞

As it is installed on the floor, the laser level is highly recommended for laser beams.

☞

It is recommended to use multiple levels and multiple personnel.

☞

It depends on the skill level, but it is recommended to use ink on the wall.

How to Use

1) Layout of Line Laser Leveling Machine and Screed Leveling Tripod

Operate the line laser level in a position where you can check the level of the floor surface.

①

Adjust the attached tripod support and use a line laser level (b) to level it.

②

Using a separate bracket, the height of the line laser level (b) and regulator can be adjusted.

- Place the Screed Leveling tripod at 1.5 ~ 2m intervals.

- If the floor is insulated and aerated concrete, the Screed Leveling tripod can be pressed against the floor surface to fix it.

2) Screed Leveling Tripod (a) adjustment

- Check the planned floor height and spacing of the laser line once with a tape measure.

- Turn the handle of the Screed Leveling tripod (a) to align the measured value of the central axis with the laser line.

- Several laser levels (b) can be used.

- Several people can operate the Screed Leveling tripod (a).

- After adjusting the height checker, collect the laser level.

3) zoning space adjustment

- After installation, install a separate laser leveler (b) where the Screed Leveling tripod (a) is visible.

- First, check the dimensions of the line of the separate laser leveler (b) on the adjusted and adjusted Screed Leveling tripod (a).

- Adjust the other Screed Leveling tripod (c) according to the checked dimensions.

4) Mortar application

- Flow mortar according to the placement height check at the bottom of the central axis of each appliance.

- Carefully spill mortar so as not to cover the installation surface.

5) Take out the Screed Leveling tripod.

- Using a screed Dapple bar, spread out the gap between each Screed Leveling tripod to the height and collect the Screed Leveling tripod (b).

- Clean the used Screed Leveling tripod (b) with water and reuse.

- Lubricating oil is applied to the central axis of the rotating screw and the ruler so that foreign matter can be easily removed.